Check out https://anixusa.com/stainless-steel-ball-valve for Anix Valve USA's wide range of wholesale ball valves.

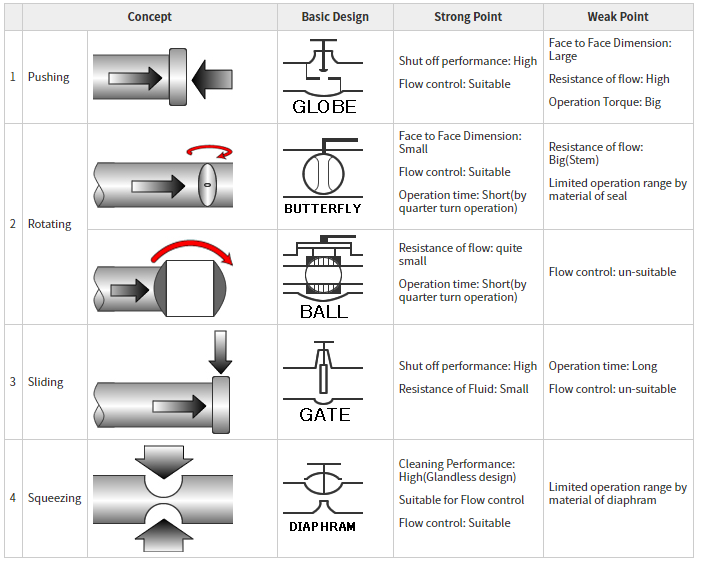

Ball valves are mechanical devices that guides, modulates and directs flows of various types of liquids by the opening of a round ball with a hole in the middle. This opening is known as the port. Turning the handle on the ball valve manually opens or closes the port. Opening or closing the port manually controls the pressure from the flow of the liquid. Ball valves are very durable so they are more advantageous than other valves. Below is a list of different valves and it can be seen that ball valves fall in the concept of rotating valves. From here we can see that the strong points of ball valves are their resistance of flow is quite small and their operation time is short. The one weak point they have is that their flow control is un-suitable.

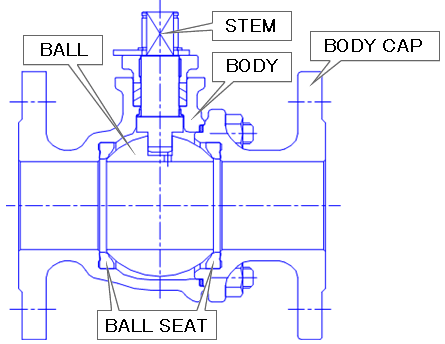

The figure below shows the construction of a ball valve.

There are five different styles of ball valves. These are the single body, three-piece body, split body, top entry and welded. The difference is based on how the pieces of the valve, especially the casing where the ball is contained, are structured. The valve operation itself is the same. In addition, there are different styles related to the bore of the ball mechanism itself.

A full port, also known as the full bore ball valve has an oversized ball in it so that the hole in the ball is the same size as the pipeline resulting in lower loss of friction. Flow of liquid is unregulated but it is larger and more expensive.

In a reduced port or reduced bore ball valve, flow of liquid through the valve is one pipe size smaller than the valve’s pipe size which results in area of flow of liquid being smaller than the pipe.

A V port ball valve has either a “v” shaped ball or “v” shaped seat. This allows for linear and equal percentage flow characteristics. When the valve is closed and opening is commenced the small end of the “v” is opened first allowing balanced flow control.

A trunnion ball valve has additional mechanical attachments of the ball at the top and the bottom which is suitable for higher and larger pressure valves (say, above 10 cm and 40 bars). A floating ball valve is a valve in which the ball is not held in place by a trunnion. In normal operation, this will cause the ball to float downstream slightly. This causes the seating instrument to compress under the ball pressing against it.

Three-way and four-way have an L-shaped or T-shaped hole through the middle. The many different ways of combinations of flow can be seen in the figure above. It can be easily seen that T valve can connect any pair of ports, or all three, together. However, the 45 degree position which might disconnect all three ports leaves no margin for error. The L valve can connect the center port to either side port, or disconnect all three, but it cannot connect the side ports together.

Multi-port ball valves which have 4-ways or more are also available, the inlet way often being rectangular to the plane of the outlets.

The materials from which the valves are made include, but are not limited to:

- Brass

- Iron

- Steel

- Bronze

- PVC

- Titanium

and more.

Ball valves can range in size from 0.2 to 11.81 inches. Complex control systems using a valve will require an actuator.

Valves are everywhere in our lives and we do not tend to notice them. For example, there are valves in our washing machines, dishwashers, refrigerators, etc. The industries that utilize ball valves usually have a need for supporting high pressure and temperatures exceeding 480 degrees.