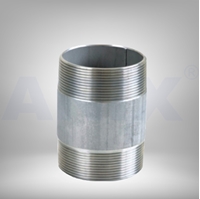

Fittings - SS316

What are fittings?

A pipe fitting is a component that helps regulate the direction of the flow, connecting different size fittings with each other and joining pumps and valves together. Usually pipe fittings are threaded or welded, mechanically joined to fit with the valve. These are some mechanisms that have the fittings and the valves or pumps join together.

Types of fittings

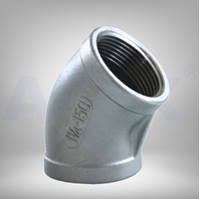

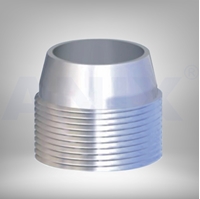

There are various types of fittings such as: elbow pipe fittings, reducer pipe fittings, tee type fittings, and cross type. Elbow type fittings allows you to reroute regularly threaded pipes to turn corners or fit in a limited space. They are made in different angles, usually at a 45 or 90 degree angle. They are usually made of different materials, made to match the pipe. Elbow fittings normally have the same threading on both ends. Reducer pipe fittings reduce the size of the pipe flow from large to small. It allows for a change in pipe size to meet hydraulic flow requirements of the system, or to adapt to existing piping of a different size by having a smaller pipe fitting. There are 2 types of reducers, concentric and eccentric and are usually concentric but eccentric reducers are used when required to maintain the same top-or bottom-of-pipe level. The reduced pipe size is achieved by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining symmetry around the fitting. The eccentric reducer reduces the pipe size by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining one side of the fitting horizontally so air can not get inside. The tee type fitting is in the shape of a t-shape, which allows 3 different components to be connected to the fitting, such as 2 inlets and one outlet. A cross type has 4 openings in 4 different directions. This is usually used when there are 4 different pipes at a meeting point. It will create more stress to the fitting as the temperature rises in the fluid. They are mostly used for sprinklers.

Fitting materials

There are 7 types of materials that they are usually made out of, which is steel, steel alloys (like stainless steels), cast iron, plastic, aluminum, copper and glass. It depends on the environment in which the fitting is best suited to resist corrosion and maintain the temperature of the fluid. Steel fittings are the most common material used because it has better resistance to corrosion. Copper and glass are used for chemicals since they both are resistant to chemicals but the glass allows a view of what is going on inside the pipe, but glass is expensive to make and it will leak out of the joints if not careful. Stainless steel is stronger than glass, but is also very expensive but is a higher quality. Plastic is another material that is very common and also cheaper, but can not be used with hot fluids as it will melt, distort, or sag.